- Home

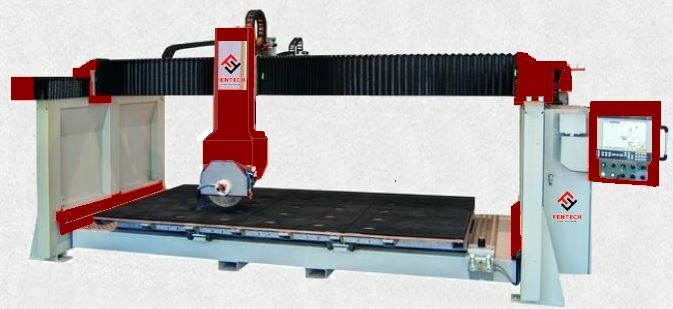

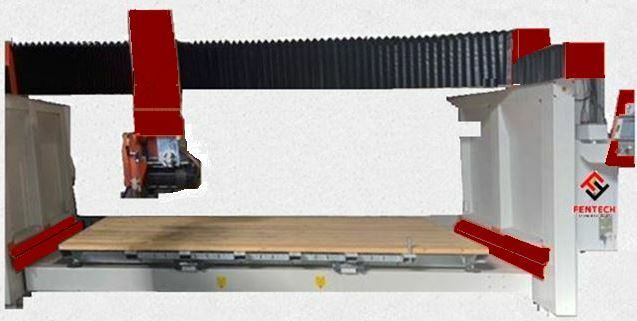

- BRIDGE SAW

BRIDGE SAW

![]()

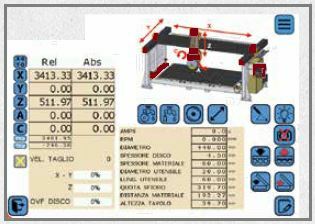

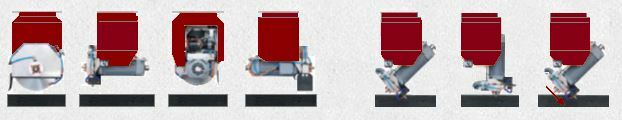

The rugged mono block basement is manufactured with electro-welded, high structural, undeformable tubular steel. Recirculating ball bearings move silently on absolutely precise linear guides made of hardened and cemented carbon steel. They are maintenance free due to the centralized automatic self-lubricating system. Top quality, strong brushless motors tirelessly move the axes and holds the blade and tool accurately in position, controlled by the NC which is managed from a operator friendly 10” touch screen.

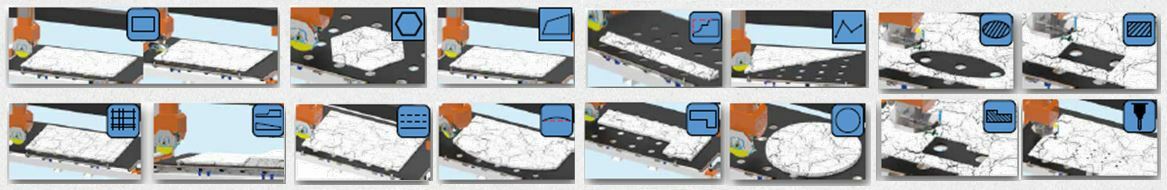

The machine can be used manually, in automatic cycle or by cnc programming.

The automatic cycle allows to set step-cutting parameters in both directions, forth and back, and also to rest the motor in its parking position at the end of the work process.

The operator can adjust the feed of the motor by a potentiometer. The motorized axes -C turns automatically 0°- 370° and -A tilts automatically 0°-90° while the positions are displayed on the touch screen.

The main motor is a powerful Italian made 15 kW (20 hp), 415V-50Hz 3-phase (or other upon request) to cut any stone material up to 150 mm thickness. An inverter controls continuously the rotation speed from 600-6000 rpm to guarantee maximum torque at any time.

Loading... Please wait...

Loading... Please wait...